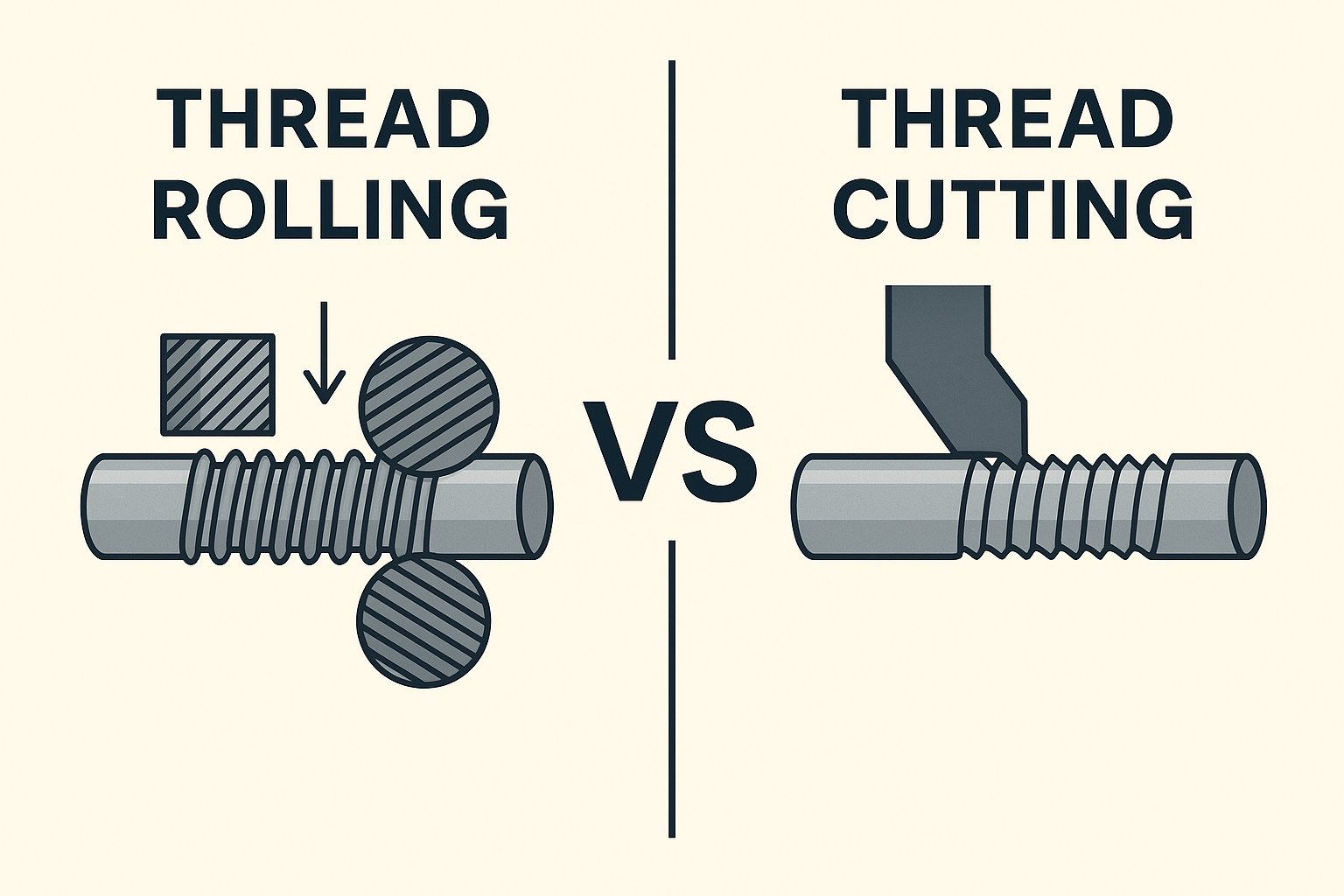

In precision manufacturing, creating strong, reliable threads is essential for the performance and safety of mechanical components. Two primary processes used to form threads—thread rolling and thread cutting—may seem similar at a glance, but the choice between them can significantly impact strength, cost, and application suitability.

So how do you decide which threading method is ideal for your application?

What is Thread Cutting?

Thread cutting is a subtractive manufacturing process where threads are machined into a workpiece using taps, dies, or a lathe. Material is removed to create the thread profile.

Key Characteristics:

Best for low to medium production volumes

Works on a wide range of materials, including hard metals

Ideal for internal and custom threads

Threads have standard mechanical strength

Greater material waste compared to rolling

What is Thread Rolling?

Thread rolling is a cold-forming process that displaces material to form threads using hardened dies. Unlike cutting, it doesn’t remove material but instead compresses it to create the desired thread geometry.

Key Characteristics:

Produces stronger threads due to grain flow and work hardening

Faster production speeds and lower cycle times

Ideal for high-volume manufacturing

Limited to ductile materials

Generates no chips – a cleaner process with minimal waste

Comparing the Two: Strength, Finish, and Efficiency

| Feature | Thread Cutting | Thread Rolling |

|---|---|---|

| Thread Strength | Standard | 20–30% stronger |

| Surface Finish | Good | Excellent |

| Material Waste | High (chips produced) | Minimal (no chips) |

| Production Volume | Low to Medium | Medium to High |

| Suitable Materials | Wide variety | Ductile materials only |

| Cycle Time | Moderate | Faster |

Real-World Applications

Many industries—ranging from automotive to hydraulics, electrical, and aerospace—use threaded parts in high-stress environments. Choosing the right threading method depends on performance requirements, material type, and production volume.

Thread rolling is typically favored for external threads on components exposed to vibration, fatigue, or pressure due to its superior strength and durability.

Thread cutting is often chosen for internal threads, prototypes, or when working with hard or brittle materials.

✅ Choosing the Right Method

When deciding between thread rolling and thread cutting, consider:

Production scale: Thread rolling excels in mass production.

Strength requirements: Rolled threads provide greater fatigue resistance.

Material: Thread cutting works on both hard and soft materials.

Thread type: Cutting is more versatile for complex or custom thread geometries.

Ultimately, both methods have their place in modern manufacturing. By aligning your threading approach with your specific application needs, you ensure performance, reliability, and cost-effectiveness in the final product.

🏁 Final Thoughts

Understanding the differences between thread cutting and thread rolling can help manufacturers make smarter design and process decisions. As technology advances and demand for high-performance parts grows, mastering these fundamental techniques will remain crucial in delivering reliable and efficient products.