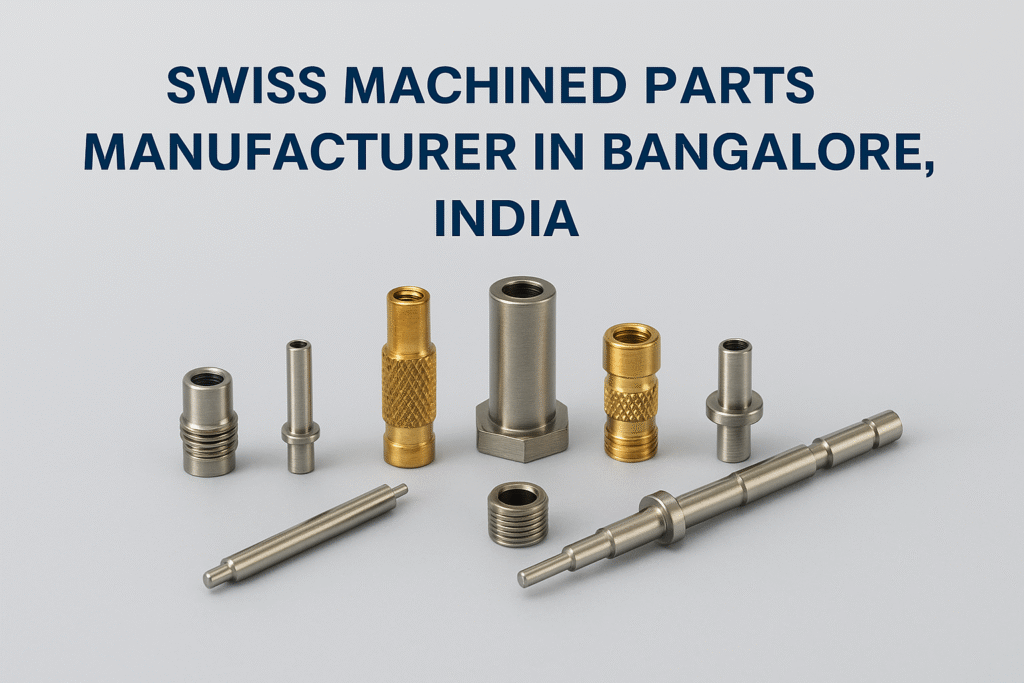

In the rapidly evolving world of precision engineering, Swiss machining stands out as a benchmark for producing ultra-precise, high-quality components used across industries like medical, aerospace, electronics, and automotive. Bangalore, India—often dubbed the “Silicon Valley of India”—has emerged as a hub for advanced manufacturing, and Mech Source is proud to be one of the region’s leading Swiss machined part manufacturers.

What Are Swiss Machined Parts?

Swiss machining refers to a highly precise turning process performed on Swiss-type lathes or sliding headstock machines. Originally developed for the Swiss watch industry, this technology is now used globally to produce small, intricate parts with tight tolerances, excellent surface finish, and remarkable repeatability.

Swiss machines differ from traditional CNC lathes in one major way: the bar stock moves in and out of the cutting zone while being supported close to the tool, which significantly reduces deflection and enables machining of very slender and long components.

Why Choose Swiss Machining?

Tight Tolerances: Ideal for parts requiring tolerances as close as ±0.005 mm.

Superior Surface Finish: Excellent finish straight off the machine, reducing or eliminating secondary operations.

Complex Geometries: Multiple operations like drilling, milling, threading, and knurling in a single setup.

Material Flexibility: Capable of machining materials like stainless steel, brass, aluminum, titanium, and engineering plastics.

Cost-Effective: Ideal for high-volume production due to reduced cycle time and automation.

Applications of Swiss Machined Parts

Swiss machined components are used in:

Medical devices: Surgical instruments, bone screws, dental implants.

Electronics: Miniature pins, connectors, sensor housings.

Automotive: Fuel injector parts, precision pins, valve components.

Aerospace: Instrumentation parts, lightweight fasteners, control system hardware.

Why Bangalore is a Strategic Location

Bangalore is not just India’s IT capital—it’s also a rising star in precision manufacturing. The city’s proximity to aerospace clusters, R&D labs, and tech-savvy engineering talent makes it an ideal location for manufacturing high-precision components using Swiss technology.

Mech Source: Your Trusted Swiss Machined Part Manufacturer

At Mech Source, we specialize in manufacturing custom Swiss machined parts using state-of-the-art sliding head CNC machines. With a fully equipped facility in Bangalore, we offer:

ISO-certified quality control systems

Customized parts as per your drawings and specifications

Advanced CAD/CAM integration for complex geometries

Quick prototyping and high-volume production

Dedicated customer support from concept to delivery

Whether you need small diameter components for the medical industry or complex turned parts for aerospace, Mech Source has the capability and expertise to deliver.

Partner With Mech Source for Swiss Machined Excellence

Sourcing Swiss machined parts from India—especially from a tech-forward city like Bangalore—gives you the advantage of cost-efficiency without compromising on precision.

🔧 Get in touch with Mech Source today to discuss your Swiss machining needs.

📞 Call us, 📩 email us, or 🖥️ visit mechsource.com to request a quote or learn more about our capabilities.