Managing tools and inserts efficiently is a critical challenge for many machine shops. At our organization, we faced ongoing issues with tracking and accounting for these essential items. Tools and inserts would go missing, operators would often forget to make ledger entries, and stock levels were unclear. This lack of control led to frequent disruptions, wasted resources, and unnecessary costs due to reordering items already in stock.

After several attempts to educate our operators and streamline processes, we realized that the root cause of the problem lay not in the personnel but in the system itself. Here’s how we transformed our tool and insert management—and how other machine shops can do the same.

The Problem: Inefficient Tool Management

- No Centralized Tracking: We relied on manual ledger entries to track tools and inserts, but operators often missed recording usage.

- Misplacement and Loss: Inserts and tools were frequently misplaced, causing delays and confusion.

- Unclear Stock Levels: Without accurate records, we couldn’t determine the value of stock on hand or plan for reorder quantities effectively.

- Frequent Reordering: Mismanagement often resulted in duplicate orders, increasing costs unnecessarily.

- Time Wasted: Searching for misplaced tools and inserts consumed valuable production time.

The Solution: A Simple System That Works

Our breakthrough came when we implemented a straightforward yet highly effective system using basic tools like Excel or Google Sheets. The key change was eliminating direct access to storage locations without a record in the system. Here’s how it worked:

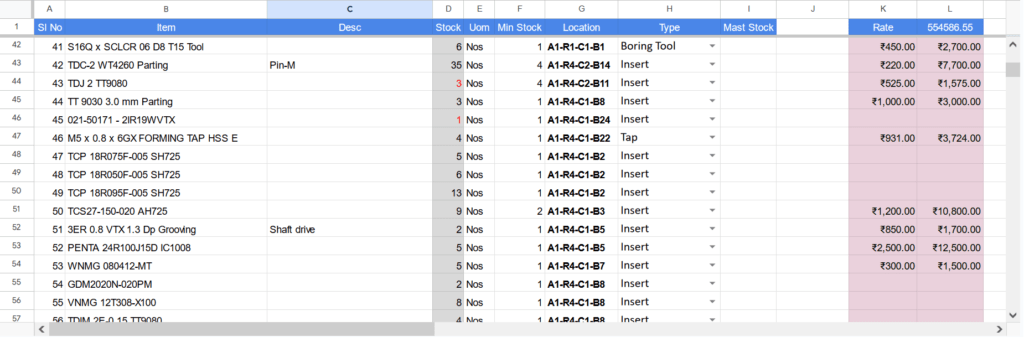

- Centralized Inventory Sheet: We created a detailed spreadsheet listing all tools and inserts, their quantities, and their storage locations.

- Location Check Before Access: Operators had to consult the system to find the location of the item they needed.

- Mandatory Entry Before Retrieval: Operators were required to log the item as “taken” in the system before accessing the storage location.

- Stock Level Monitoring: The system automatically updated stock levels in real time, helping us track quantities and reorder points.

- Reorder Alerts: With the data on hand, we could monitor minimum stock levels and reorder inserts and tools before running out.

The Results: Transforming Inventory Management

This simple change brought remarkable benefits:

- Accurate Stock Records: We now have a clear, real-time picture of all tools and inserts in stock.

- Reduced Wastage: Misplacement and loss of tools dropped significantly, saving money and resources.

- Streamlined Reordering: Knowing exact stock levels and reorder points prevents unnecessary purchases and production delays.

- Improved Accountability: Operators became more responsible, as the system required their participation to retrieve items.

- Cost Savings: With better stock control, we reduced waste and unnecessary expenses, improving our bottom line.

How This System Can Help Other Machine Shops

If your machine shop faces similar challenges, implementing this simple system can save you time, money, and effort. Here’s how to get started:

- Digitize Your Inventory: Use a basic Excel sheet or a cloud-based tool like Google Sheets for accessibility.

- Create Unique Locations: Assign each tool or insert a specific storage location and record it in the system.

- Enforce System Use: Make it mandatory for all staff to check the system before accessing tools and log entries for withdrawals.

- Monitor Stock Levels: Regularly review stock data to ensure sufficient quantities and prevent overordering.

- Train Your Team: While the system is simple, a one-time training session ensures everyone understands and follows the process.

A Simple Solution, Big Impact

Our experience demonstrates that even a straightforward system can have a profound impact on tool and insert management. By making inventory data central to the process and requiring operators to engage with it, we solved a longstanding problem and streamlined our operations.

For any machine shop struggling with inventory challenges, adopting a similar system can lead to significant improvements in efficiency, accountability, and cost savings. Simple tools, combined with clear processes, can truly transform your business operations.

Struggling to manage tools and inserts effectively in your machine shop? You may connect with us for support in implementing a simple, efficient system to streamline inventory management and improve your operations!