A Beginner’s Guide

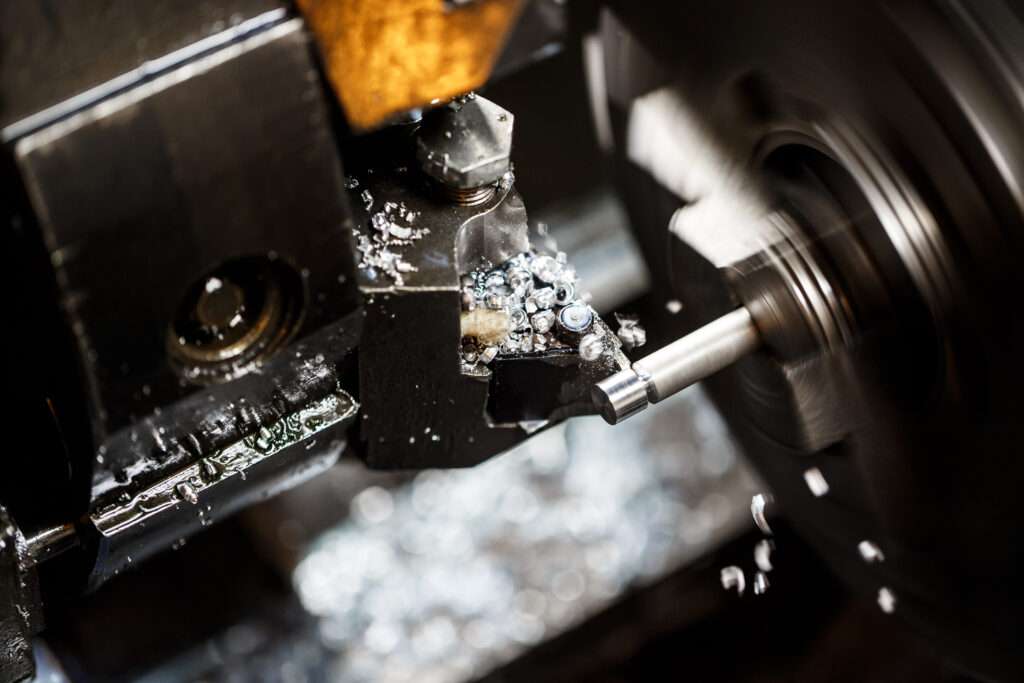

What is a CNC Lathe?

A CNC lathe is a machine tool used to shape workpieces by rotating them around a fixed cutting tool. Unlike a manual lathe, where a machinist manually controls the cutting movements, a CNC lathe is controlled by a computer, using programming instructions (known as G-codes and M-codes). These instructions define the machine’s movements, tool changes, speeds, and other critical parameters.

The CNC lathe can perform various operations, including:

- Facing: Cutting the end surface of the workpiece.

- Turning: Reducing the diameter of the workpiece by removing material.

- Boring: Enlarging an existing hole.

- Threading: Cutting external or internal threads on the workpiece.

Key Components of a CNC Lathe

Before diving into programming, it’s important to understand the main parts of a CNC lathe:

- Chuck: This is the component that holds the workpiece in place while it rotates.

- Spindle: The part that rotates the chuck and the workpiece at high speeds.

- Tool Turret: A rotating component that holds multiple cutting tools and switches between them as needed.

- Tool Post: Holds the cutting tool at the correct position during machining.

- Tailstock: Provides additional support for longer workpieces.

- Control Panel: This is where the operator inputs commands or loads the CNC program.

Understanding CNC Codes: G-Code and M-Code

The heart of CNC lathe programming lies in G-codes and M-codes, which are the commands used to control the machine.

G-Codes (Geometric Codes): These are used to control the movement of the machine, such as moving the tool in a straight line, creating arcs, or changing the feed rate. Common G-codes include:

- G00: Rapid movement to a specified position.

- G01: Linear feed movement for cutting.

- G02: Clockwise arc cutting.

- G03: Counterclockwise arc cutting.

M-Codes (Miscellaneous Codes): These codes control the auxiliary functions of the machine, such as starting or stopping the spindle, turning the coolant on or off, or changing tools. Examples include:

- M03: Start the spindle in a clockwise direction.

- M05: Stop the spindle.

- M06: Tool change command.

- M08: Turn coolant on.

Writing a Simple CNC Lathe Program

Now that you understand the basic components and codes, let’s write a simple CNC lathe program. We’ll assume we want to face a cylindrical workpiece and then perform a basic turning operation.

Program Example:

Breaking Down the Program:

- O1000: This is the program number.

- G21: Sets the units to millimeters (alternatively, G20 would set the units to inches).

- G18: Selects the XZ plane, which is typical for lathe operations.

- G40: Cancels tool radius compensation (used for more advanced operations).

- G54: Selects the work coordinate system (a standard setup).

- M06 T0101: Selects tool 1 with tool offset 1.

- M03 S1500: Starts the spindle rotating clockwise at 1500 RPM.

- G00 X50 Z5: Moves the tool rapidly to a safe position of 50mm in the X direction and 5mm in the Z direction.

- G01 Z0 F0.2: Feeds the tool to Z0 at a feed rate of 0.2mm per revolution, starting the cutting operation.

- G01 X0: Moves the tool to X0 to face the end of the part.

- G00 X50 Z5: Retracts the tool to a safe position after the operation.

- M05: Stops the spindle.

- M30: Ends the program and resets the machine.

Tool Path Visualization

It’s important to visualize the tool’s path when programming. In the above example, the tool first moves rapidly to a safe position, then cuts along the Z-axis to face the part, and finally moves along the X-axis to complete the facing operation. The tool then retracts to a safe location, ensuring it won’t collide with the workpiece during the next steps.

Tips for Beginners

- Start Simple: Begin with straightforward operations such as facing or turning and gradually progress to more complex tasks like threading and grooving.

- Simulate Before Running: Most CNC controllers have simulation features that allow you to preview the tool path and ensure the program will run correctly before engaging the machine.

- Use Tool Offsets Correctly: Properly setting and understanding tool offsets will help you maintain precision and reduce the risk of errors.

- Understand Material Properties: Different materials respond to cutting differently. Adjust your feed rates and speeds accordingly.

Conclusion

CNC lathe programming may seem complex at first, but once you grasp the basics of G-codes, M-codes, and tool movement, it becomes much more manageable. By practicing with simple programs and visualizing tool paths, you’ll quickly gain confidence in operating and programming CNC lathes. Over time, this skill will allow you to efficiently produce precision parts and tackle more advanced machining operations.