Introduction

In today’s fast-paced manufacturing world, machine shops face increasing pressure to improve efficiency, reduce costs, and maintain high-quality standards. With competition intensifying, automation presents a golden opportunity for small and medium-sized enterprises to revolutionize their operations. Whether you are looking to streamline processes or enhance productivity, embracing automation can lead to significant benefits. In this blog, we’ll explore the top five game-changing automation ideas tailored specifically for machine shops.

1. Implementing Automated Workflows

What It Is

Automated workflows help eliminate repetitive tasks, allowing your team to focus on value-added activities. By creating a streamlined process for order management, inventory control, and production scheduling, you can save time and reduce errors.

Real-World Example

One machine shop integrated an automated software system for tracking orders. This system reduced manual entry errors by 30% and cut order processing time by half, significantly improving customer satisfaction.

Action Steps

– Assess your current workflow to identify repetitive tasks. – Research available software solutions that suit your needs. – Train your staff on how to use the new system effectively.

Benefits

– Increased efficiency and accuracy. – Enhanced customer service due to quicker response times. – Ability to reallocate human resources to higher-value tasks.

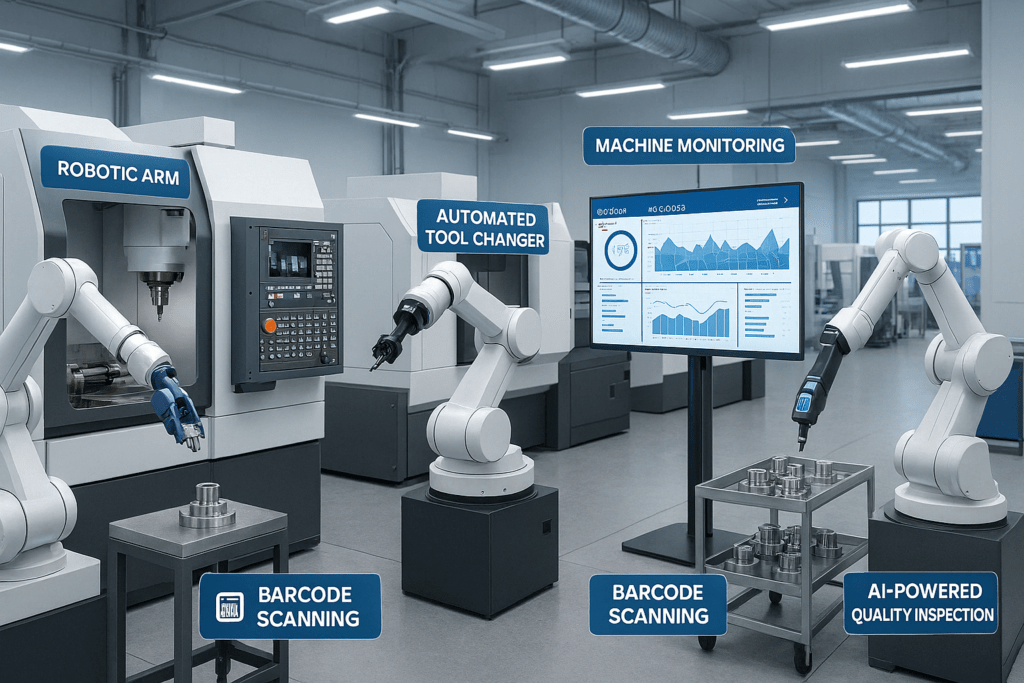

2. Investing in CNC Machines with Automatic Tool Changers

What It Is

CNC (Computer Numerical Control) machines equipped with automatic tool changers streamline machining operations. They can switch tools automatically without human intervention, enhancing production rates.

Real-World Example

A mid-sized machine shop that adopted CNC machines with automatic tool changers noted a 50% increase in production capacity, allowing them to take on larger contracts and fulfill orders faster.

Action Steps

– Evaluate your machining needs and compare various CNC machines on the market. – Invest in CNC technology that supports your shop’s growth trajectory. – Train your operators on proper CNC programming and maintenance.

Benefits

– Improved production capabilities. – Consistent quality due to precise tool changes. – Reduction in labor hours spent on manual tool changes.

3. Utilizing Inventory Management Automation

What It Is

An automated inventory management system tracks supplies and materials in real-time, ensuring that you never run out of essential items while minimizing excess inventory.

Real-World Example

One machine shop used an automated inventory system that alerted staff when stock levels were low. This led to a 20% reduction in inventory costs and prevented service disruptions due to stock shortages.

Action Steps

– Implement a cloud-based inventory management system that integrates with your current operations. – Regularly update data to ensure accuracy. – Train your employees on how to use the system effectively.

Benefits

– Reduced waste and storage costs. – Enhanced ability to plan production schedules based on material availability. – Improved cash flow management.

4. Scheduling Automation for Job Prioritization

What It Is

Automated scheduling systems help prioritize jobs based on deadlines, materials, and labor availability. This ensures that your resources are allocated efficiently.

Real-World Example

A machine shop that implemented scheduling automation saw a 25% increase in on-time deliveries, improving customer trust and enabling the business to take on more projects.

Action Steps

– Invest in scheduling software that fits your operational needs. – Set up key performance indicators (KPIs) to measure scheduling efficiency. – Regularly review and adjust your scheduling criteria based on experiences.

Benefits

– Better workforce management. – Enhanced ability to meet customer deadlines. – Increased profitability through more effective use of resources.

5. Embracing Predictive Maintenance Technologies

What It Is

Predictive maintenance uses data analytics to predict equipment failures before they occur. By monitoring machine health, you can schedule maintenance only when necessary.

Real-World Example

A machine shop that employed predictive maintenance managed to reduce machine downtime by 40% by addressing potential issues before they impacted production.

Action Steps

– Equip machines with sensors that track performance metrics. – Analyze data regularly to identify trends and potential failures. – Develop a scheduled maintenance plan based on predictive insights.

Benefits

– Increased machine lifespan and operational efficiency. – Cost savings by avoiding major repairs. – Higher production reliability and output.

Conclusion

Adopting automation is no longer a luxury for machine shops; it is a necessity to remain competitive in today’s market. By implementing these top five automation ideas—automated workflows, CNC machines with automatic tool changers, inventory management automation, scheduling automation, and predictive maintenance—you can significantly enhance your operating efficiency and overall business performance. Investing in these automation solutions will not only streamline processes but also empower your workforce, leading to a thriving machine shop capable of meeting modern manufacturing demands. We encourage you to share your thoughts on these automation ideas in the comments below. If you found this post valuable, please subscribe to our blog for more informative content and share this article with your peers in the industry. Let’s automate for a better future!